COMPANY

More than half a century of experience at your service

In a disused workshop at the beginning of the 1960s, Attilio Celli founded, with some partners, a metalworking company. Young students who have just graduated from the school where he himself teaches also work there. Together they learn that to grow you need trust, energy, skills, commitment, professionalism, creativity and satisfaction. This wealth of experience and life is now in the hands of his son Pierenzo Celli, founder of Mo.Des, which led the company to follow a rapid evolutionary path, leaving national borders to export its molds all over the world.

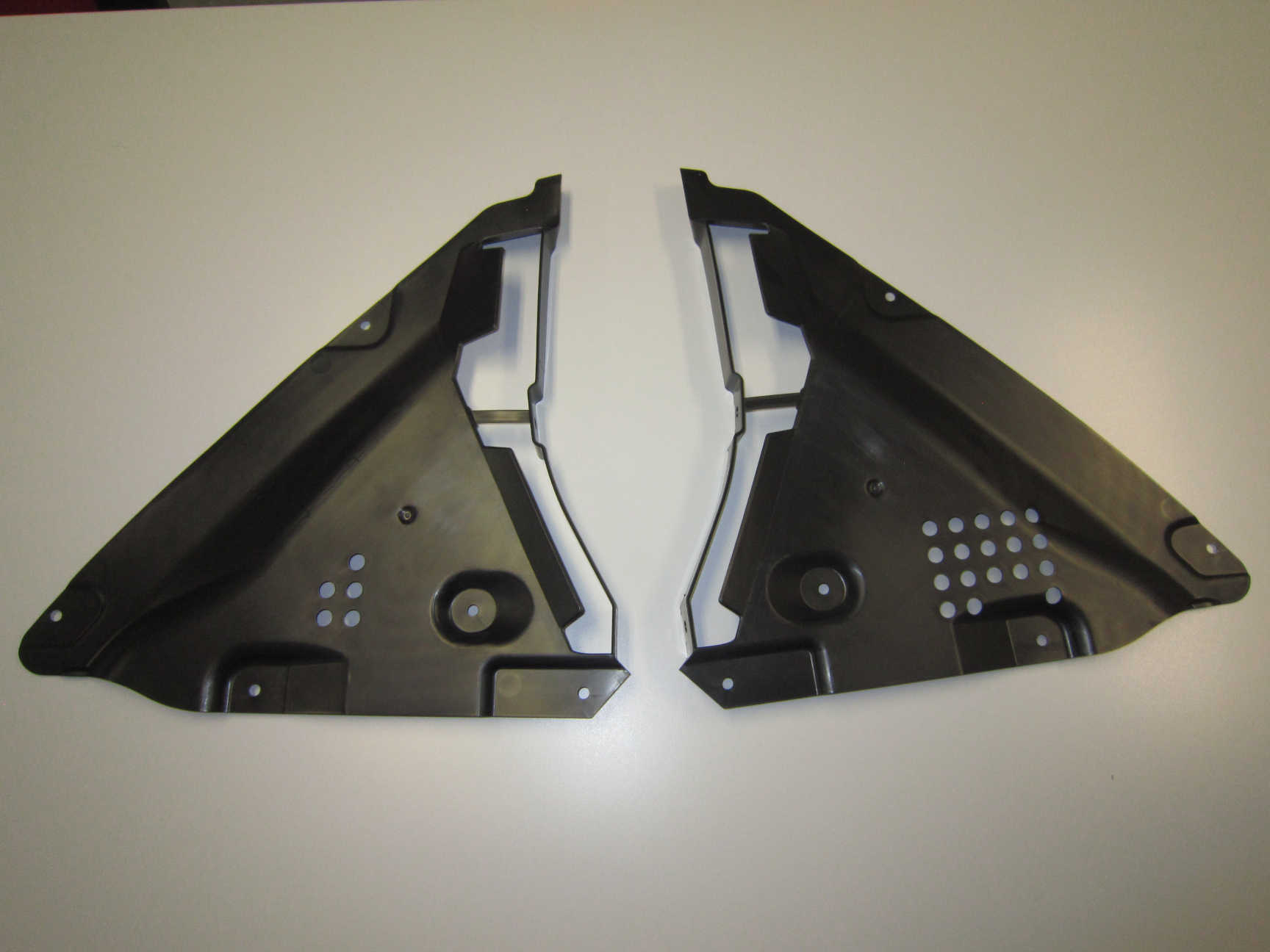

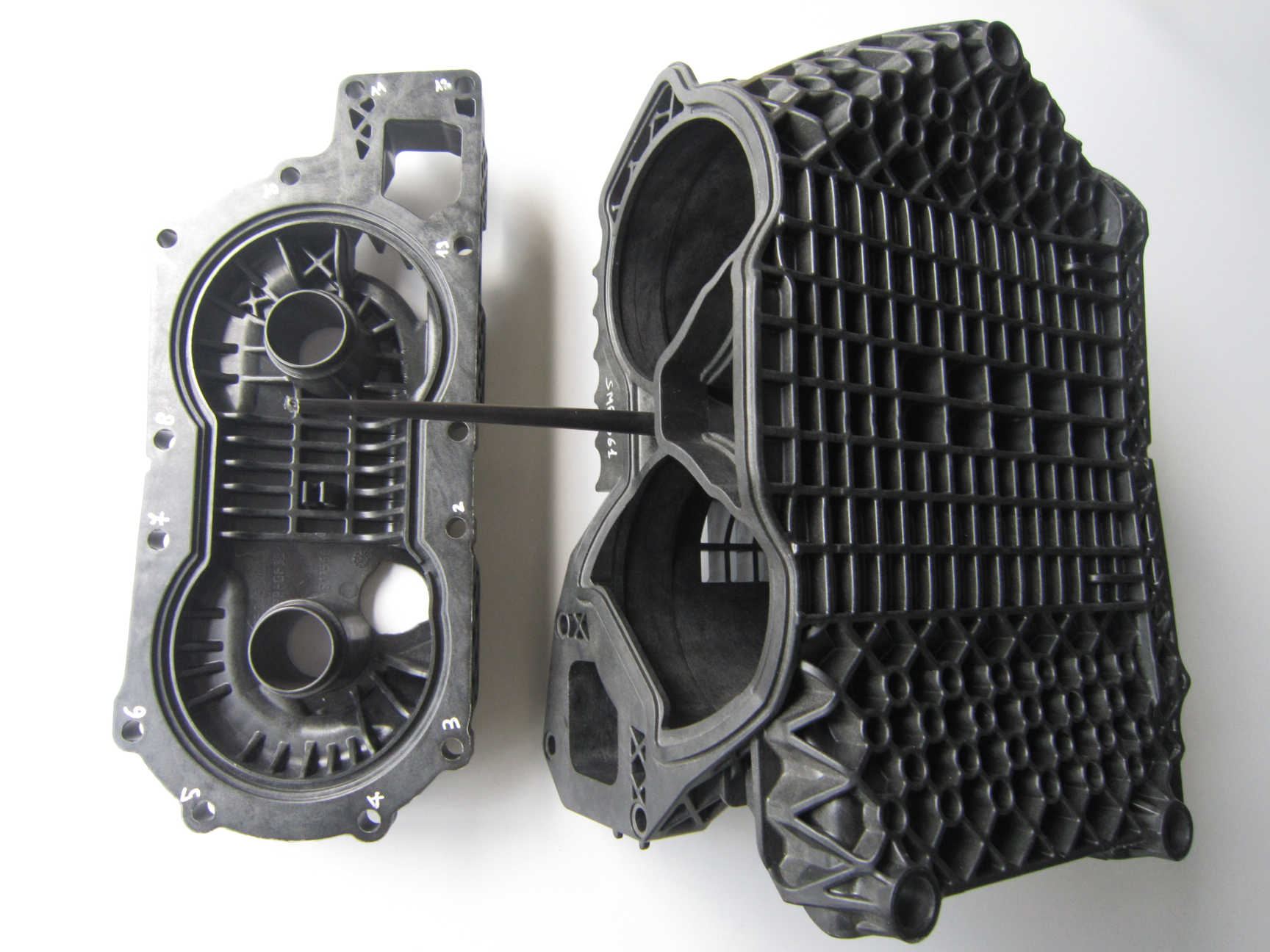

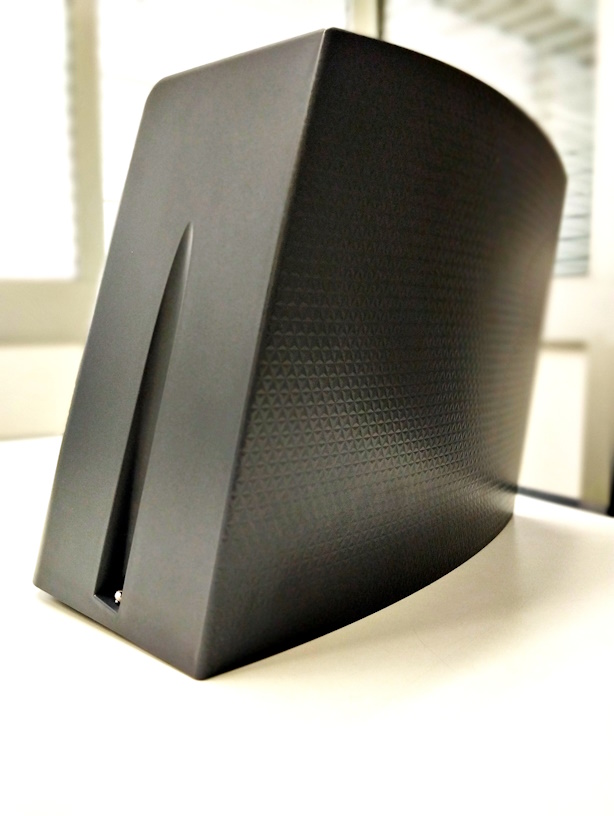

MO.DES is a leader in the sector of design, mold production and material molding plastics both for automotive and mass production. The company has been operating in Italy and Europe since 1986 and represents a point of reference for professionality and reliability for those looking for a partner capable of providing not only a excellent final product but also a constant customer support service for all their needs.

The service we offer is complete: we design and build the molds and possibly thanks to our own internal molding department we can also produce the finished product. The use of advanced technologies to design and build the mold and the optimization of the systems production, the competence of the staff and the desire to grow make MO.DES a constantly evolving reality evolution that addresses the market with determination and with multiple possibilities to satisfy the needs customer needs. Discover the quality of our mold production, plastic molding and services that we can offer you: browse the site and contact us for more information.

SERVICES

The added value we offer to our customers

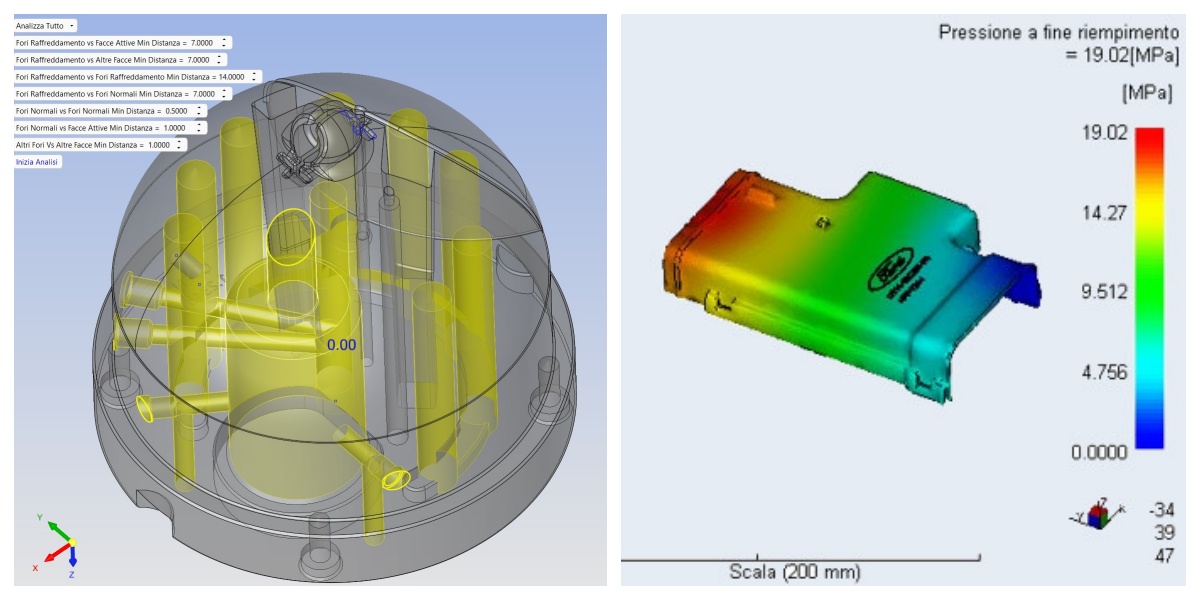

FEASIBILITY ANALYSIS

In this phase of work the MO.DES team analyzes the project both in terms of printability and creation of the equipment, also consulting our most trusted suppliers.

For more complicated projects, feasibility studies complete with analyzes are provided to the customer moldflow. MO.DES is constantly listening to customer requests as each project has its own story, we do not limit ourselves only to producing a high precision mould: each customer has different needs and it is our task to follow the project until it is put into production, however complex and long it may be process may be.

If you want to propose your ideas or if you want to ask us for an opinion on the feasibility of your projects click on contacts and explain your ideas to us.

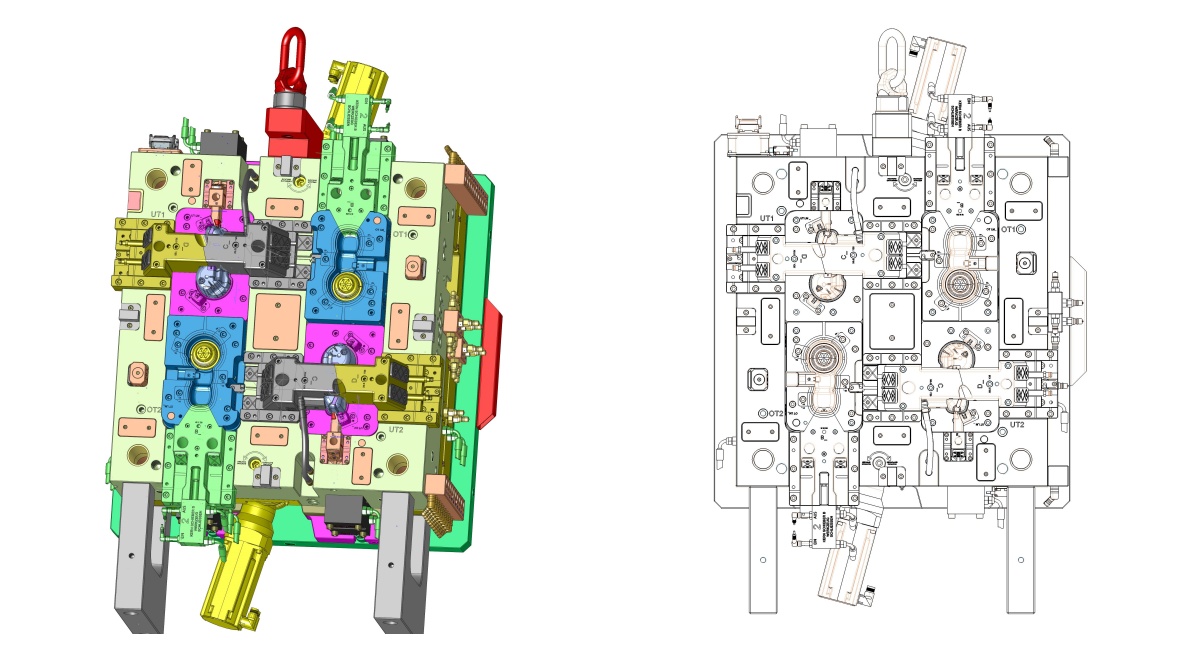

DESIGN

The project is followed by the project manager. The technical office follows the technical indications collected in the analysis/estimate phase;

- The mold design always begins with a complete collection of design details from customer: type of polymer used and relative shrinkage value, geometric tolerances required in the dimension table, requested steel type / suitable molded plastic, mold holder material;

- Once approved internally, the 3D model is available to the customer and sent for approval;

- Once the mold model is approved by the customer, the technical office continues its activity purchasing the material and sharing all the construction details with the production.

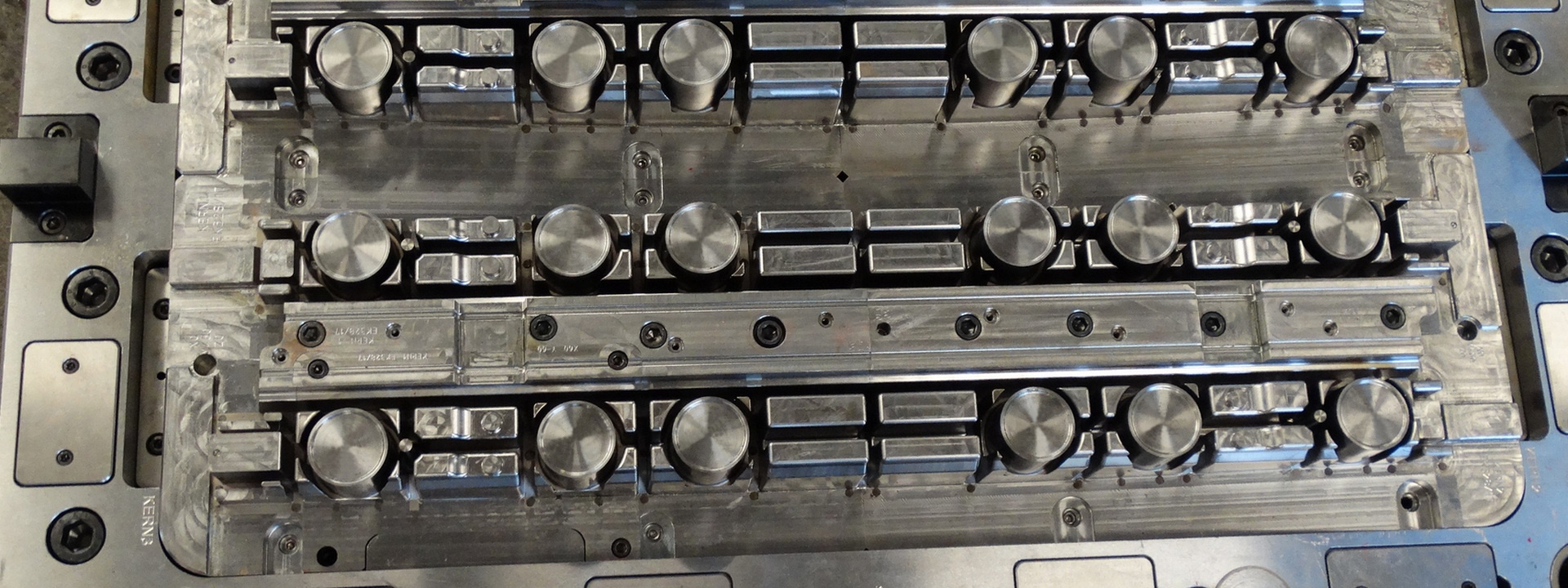

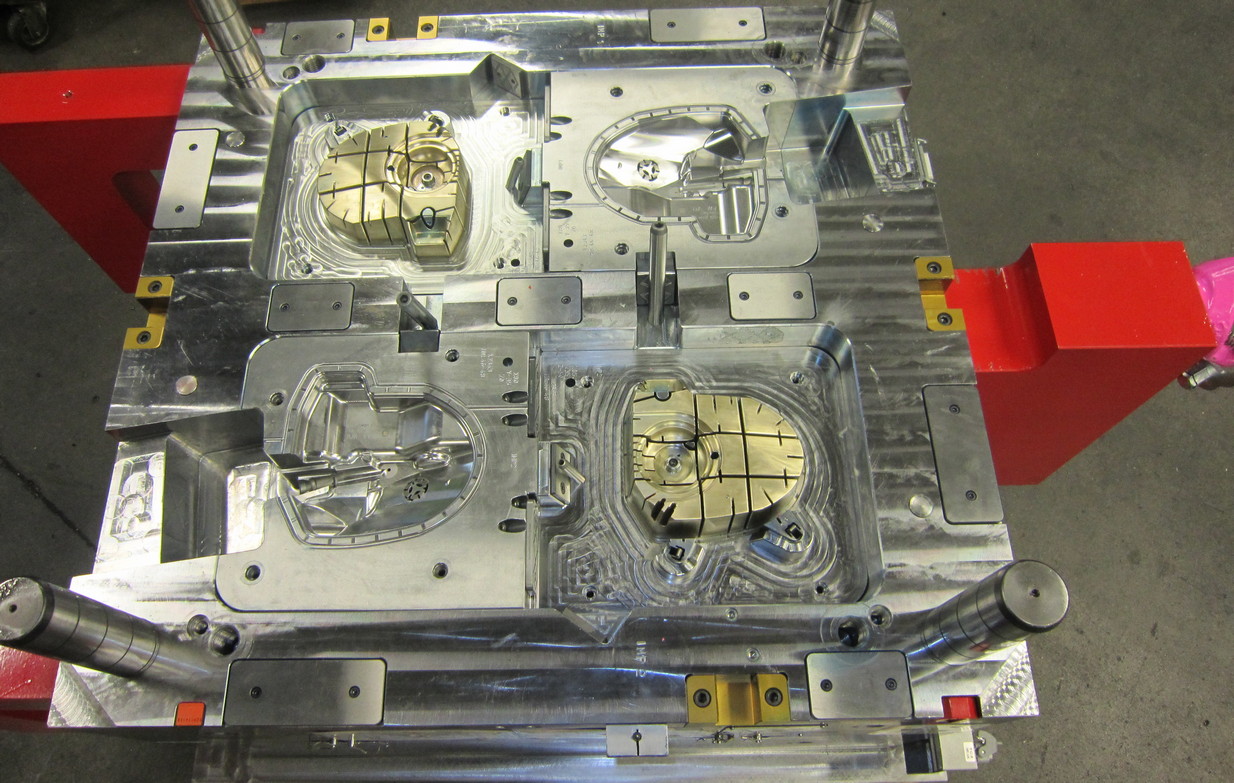

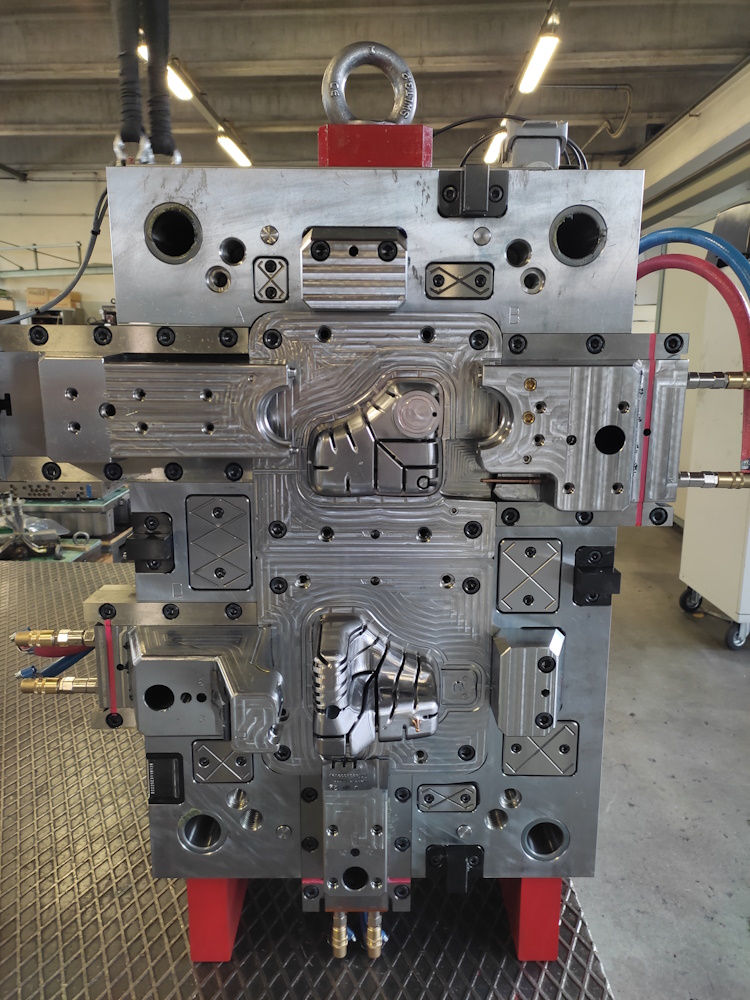

CONSTRUCTION

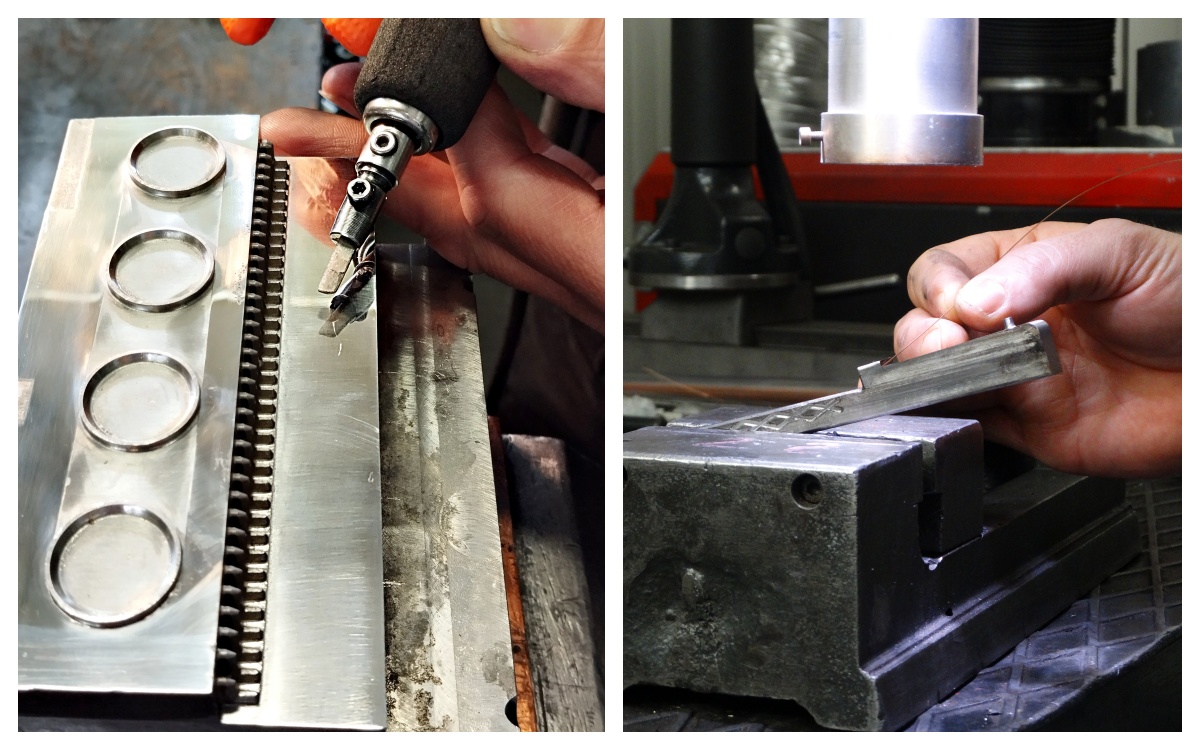

MO.DES relies on innovative technologies and advanced organizational methods:

- The department for milling operations is air-conditioned at a constant temperature of 22 °C ± 2 °C and is equipped with 3 and 5 axis milling machines for processing all copper and graphite steels, lathes, grinding, wire and dip EDM. We also have a laser welding machine;

- Production is organized with monthly schedules, weekly schedules and reports daily progress;

- The planning of activities is detailed for each individual component and work phase;

- Progress is monitored via MES software;

- The data is available in real time and, upon request, the detailed progress report is shared with the customer at regular intervals.

If you would like more information about our fleet or a more detailed presentation, fill out the form contacts and you will be contacted as soon as possible.

MAINTENANCE

In addition to the main activity of designing and manufacturing molds, we manage maintenance and reconditioning of MO.DES molds and those of other manufacturers. Our technologies allow us to carry out even simple reverse-engineering works: to go back up to the 3D model of complex geometries we can make use of the best suppliers.

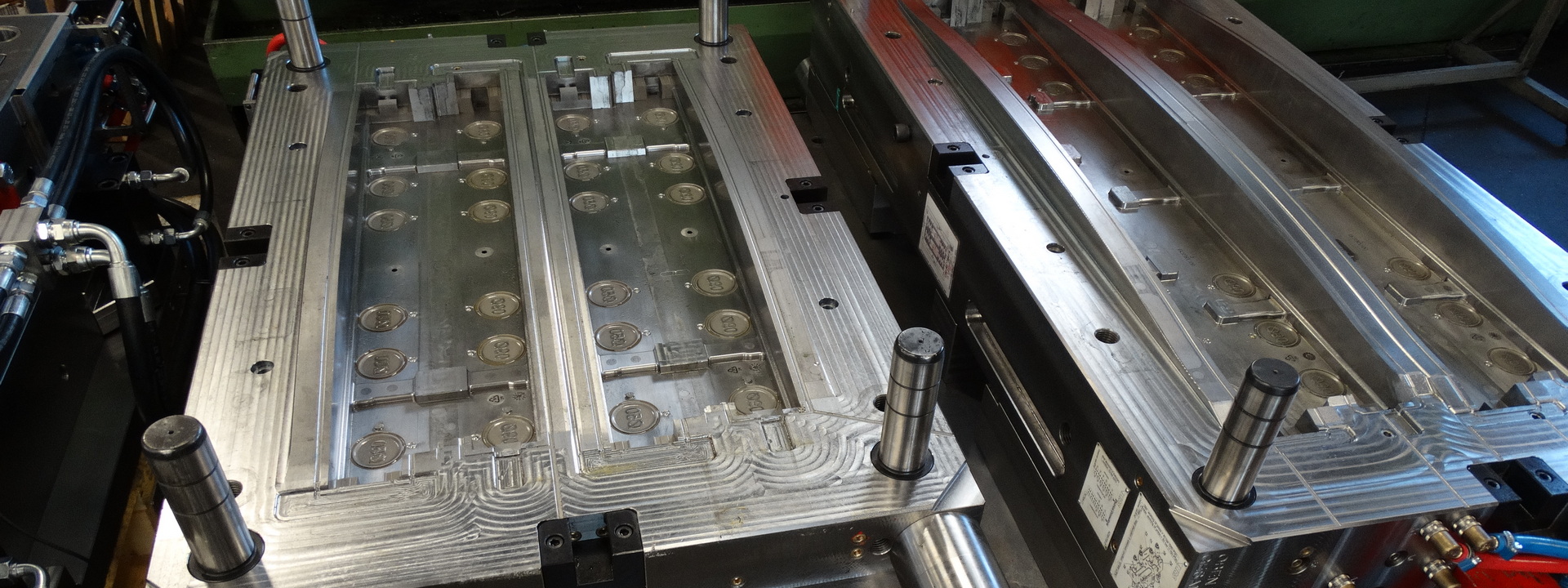

MOLD TESTS

Most mold tests are carried out internally. The screws in use are standard and allow to process all common plastic materials.

The testing phase, if the dimensions of the mold allow it, can be carried out internally with our moulding machines.

The weight of the single molding can vary from 10g to 1000g, with co-molding with a sandwich head instead it can even reach 1500g

For larger molds we can use external suppliers, equipped with horizontal presses up to 1000t.

INTERNAL MOLDING DEPARTMENT

Thanks to our variety of moulding machines which varies from 50t to 320t with dual-material molding capacity and thanks to the many years of experience gained with our prestigious clients, MO.DES is able to guarantee a high quality printed product that complies with traceability standards at every stage of production from the raw material to the finished boxed product.

CERTIFICATIONS

The guarantee of the quality of our products for our customers.

The certifications achieved and renewed over the years are tangible proof of the commitment that our company dedicates in pursuing a path of continuous improvement of its quality standards, all to always offer our customers the best result with the highest quality

CONTACTS

Street Nazionale 10, 32030

Busche di Cesiomaggiore (BL), Italy

info[AT]modesstampi.it

+39 0439 390251